For decades ductless fume hoods and filtered workstations have provided benefits to laboratory personnel throughout the world while providing a greener and more flexible laboratory design. Improvements in detection technology have expanded the application for filtered hoods thus increasing the overall advantage to laboratories in the areas of cost savings and environmental impact. Here are four key benefits of ductless fume hoods:

1. Economical

The operation cost of a ductless fume hood is substantially lower than a traditional labratory fume hood because it requires no installation. Each Dealye Systems unit has been calibrated, certified for operation and ready to use upon delivery. Conventional hoods require installation of a blower, ductwork through the building and assembly of the fume hood. All of this takes time and money.

The operation cost of a ductless fume hood is substantially lower than a traditional labratory fume hood because it requires no installation. Each Dealye Systems unit has been calibrated, certified for operation and ready to use upon delivery. Conventional hoods require installation of a blower, ductwork through the building and assembly of the fume hood. All of this takes time and money.

2. Portable

HVAC-free ductless fume hoods can be moved and operational in minutes where conventional laboratory enclosures may be out of service for weeks. Beyond the power cord, a ductless enclosure has no external connections preventing a location change and can be placed on a cart and moved from room to room.

Traditional lab hoods require a third party to move exhaust duct work and other connections before the unit may be relocated.

3. Environmentally Friendly

Ductless filtration recycles existing room air while cleaning the chemical mixture. No harmful fumes or vapors are released into the environment. The bonded carbon filter can be safely disposed of in a landfill once saturated.

4. Safe

Advanced monitoring and safety controls have allowed ductless hoods and filtered workstations to continue gaining acceptance in a variety of laboratory applications. Constant monitoring of face velocity and filtration is critical to the safety of laboratory personal.

The DealyeSafe family of automatic safety controllers monitor airflow and filter condition constantly to ensure operator safety.

Real time gas sensor technology ensures protection of the operator and other personnel from exposure to toxic chemical fumes and vapors.

Alarms are audible and visible to alert user of filter saturation.

Alarms are set per current ACGIH standards for TLV of known chemicals.

State-of-the-art airflow sensor takes a constant reading of face velocity and provides this information in linear feet per minute (LFM) to the user on the LCD monitor.

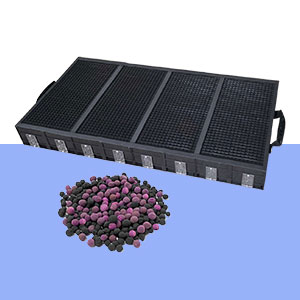

Dealye Systems bonded carbon filters are either 3 inches or 4 inches thick and have even distribution of carbon throughout the entire filter.

Dealye Systems general-purpose filter will adsorb a percentage of almost every chemical. For those chemicals that are not adsorbed well, we use a chemical impregnate to alter the target chemical.